- 01-212025

Why is stainless steel strip used in the manufacturing of mobile phone components

Stainless steel strips are widely used in the manufacturing of mobile phone components, mainly due to their ability to meet a series of characteristics that meet the needs of mobile phone manufacturing, such as performance, appearance, and durability. Here is a detailed introduction for you:

- 01-142025

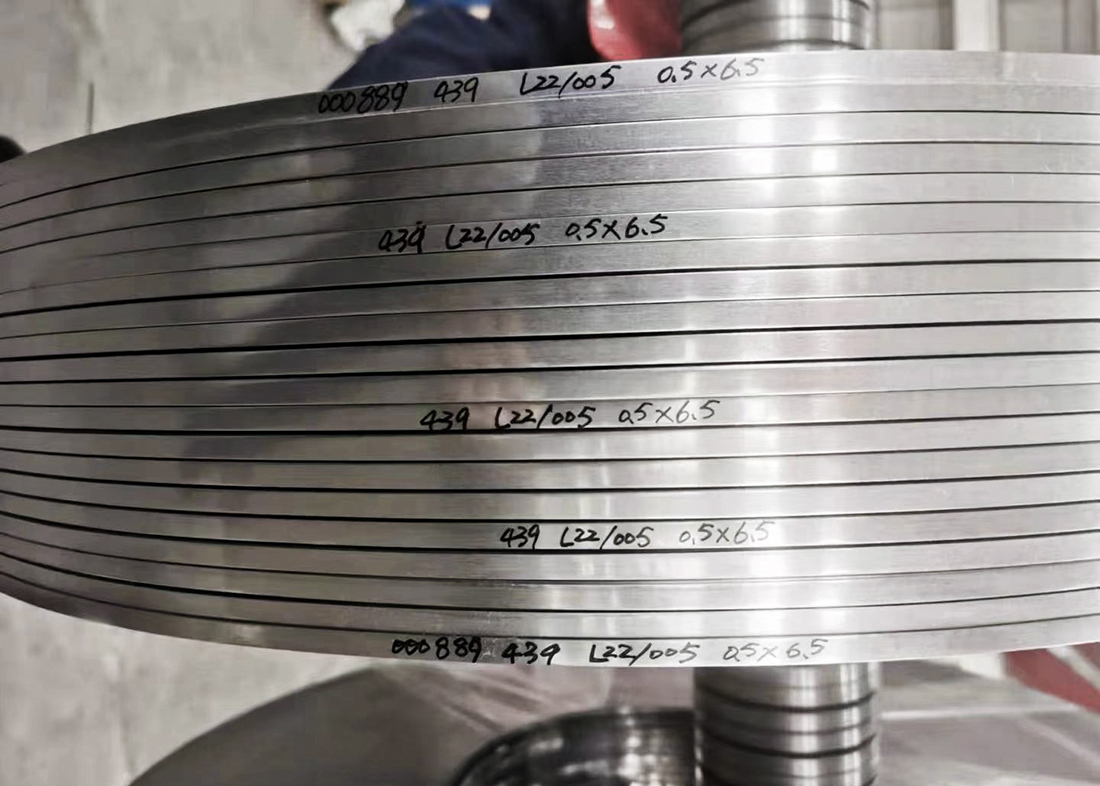

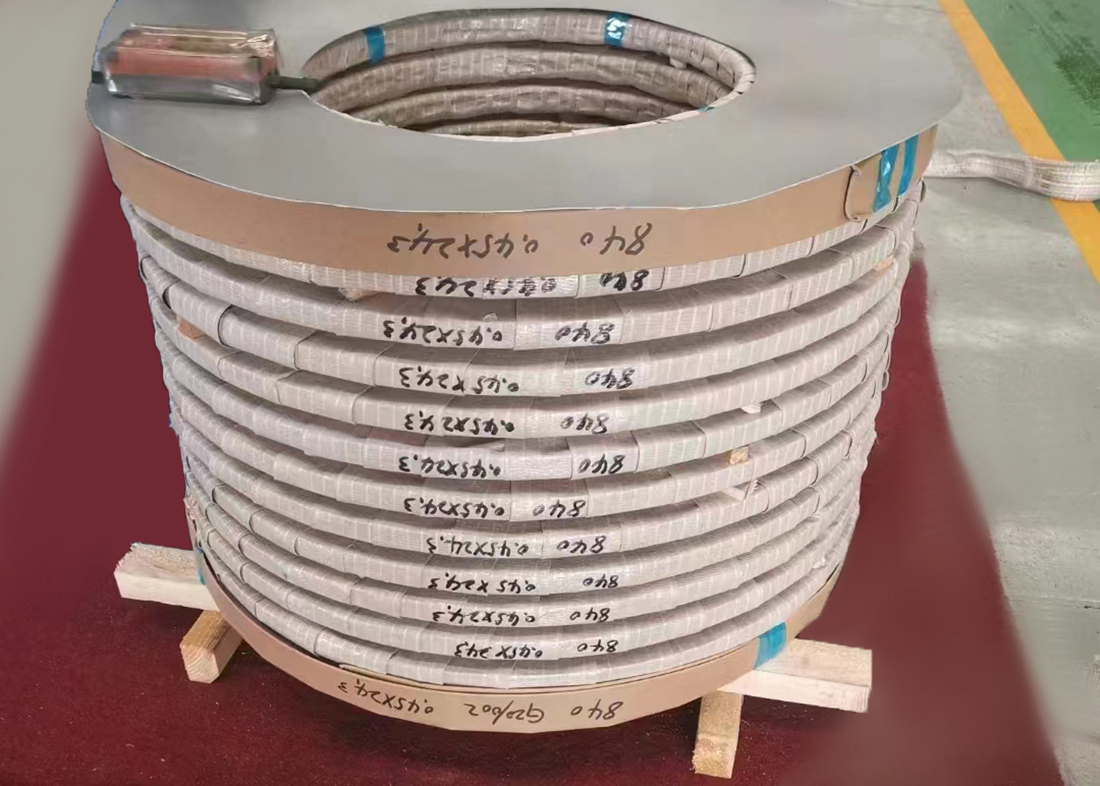

What are the cutting methods for stainless steel coils

Stainless steel coils have high flexibility in processing, reflected in multiple dimensions: 1. Shape shaping flexibility Cutting: Stainless steel coils can be easily cut into different sizes of plates according to specific needs using equipment such as shearing machines and laser cutting machines. Whether it is making large-area decorative panels or small-sized components, they can be cut

- 01-082025

How flexible is the processing of stainless steel coils

Stainless steel coils have high flexibility in processing, reflected in multiple dimensions: 1. Shape shaping flexibility Cutting: Stainless steel coils can be easily cut into different sizes of plates according to specific needs using equipment such as shearing machines and laser cutting machines. Whether it is making large-area decorative panels or small-sized components, they can be cut

- 01-012025

Why is stainless steel coil used on storage containers

The use of stainless steel coils on storage containers is mainly based on the following reasons: 1. Excellent corrosion resistance Anti medium erosion: Storage containers often need to hold various liquids, gases, or solid materials, such as acid-base solutions in the chemical industry, fruit juice and milk in the food industry, and various pharmaceuticals in the pharmaceutical industry.

- 12-252024

Why do many factories choose stainless steel coils

Many factories choose stainless steel coils mainly for the following reasons: 1. High processing flexibility On demand cutting: Stainless steel coils are continuous rolls, and factories can correctly cut them into plates or steel strips of different lengths and widths according to their own production needs, adapting to diverse product size specifications. For example, in kitchenware manuf

WeChat ID:goldinn.cn

WeChat ID:goldinn.cn

Add WeChat

Add WeChat

Contact us

Contact us

The phone

The phone